PRODUCTS

Magnetic Rods SM

Permanent magnetic rods can be integrated at any point in the material flow of solid and liquid media to separate ferrous metals. With very high magnetic forces finest ferromagnetic particles and magnetised stainless steel particles are reliably separated. Bar magnets in EASY CLEAN design can be pulled out of the stainless steel sleeves for easy cleaning. Depending on requirements, various magnetic materials (e.g., high energy neodymium-iron-boron or high-temperature resistant samarium-cobalt magnetic material) may be used.

Grird Magnets GM

Permanent magnet grid magnets are available in round, rectangular or square design and can therefore be used universally for free-flowing bulk solids (eg in pipe systems, hoppers or chutes). Ferrous particles are filtered out of the bulk material as they pass through the magnetic grid. Depending on the requirements, the grid magnets are supplied as a fixed unit or with removable magnet cores for cleaning relief (EASY CLEAN). Various magnetic materials (e.g., high energy neodymium-iron-boron or high-temperature-resistant samarium-cobalt magnetic material) are available to suit the respective requirements.

Magbox MX

Robust magnetic grid system in housing for installation in free-fall lines. The connection flanges can be customized. For the highest purity requirements, multi-layer systems are available. Magnetic grids are available with withdrawable magnetic cores (EASY CLEAN) or as a fixed unit. As a special design, ATEX approved systems or housings with highly polished surface are available as pharmaceutical version.

Plate Magnet PM

Plate magnets are designed to separate ferrous impurities in a continuous flow of material through conveyors, in free fall or under slides and slideways. Depending on the application, different magnetic materials (ferrite or high energy neodymium-iron-boron) are used for plate magnets. As a special design also plate magnets on support profiles for long spans are available for applications like the textile industry.

Chute Magnet PRM

Primarily for the magnetic separation of easily 'bridging' and fibrous products, these chute magnets find their application. Even with very high throughput rates and pipelines with slight overpressures, these systems have proven themselves very well. Versions with manual cleaning (EASY CLEAN) or automated systems (AUTO CLEAN) are available.

Pneumag PG

Magnetic grid system in housing for installation in pneumatic conveying lines with high flow speeds (up to 25m / s) or free-fall lines. Optionally available in ATEX and pharmaceutical version with highly polished surfaces.

Liquimag LM

This magnet system was developed especially for the inspection of liquid and pasty products. In the double-walled version, the housing can be heated. Thanks to EASY CLEAN design, effective and fast cleaning of the magnet system is ensured. With the Liquimag AUTO CLEAN a self-cleaning variant is available.

Inline Magnet RM

These magnetic separators for solids with limited flow properties are integrated into the pipeline and form a solid unit with it. On the inside of the housing are deflectors, which distribute the material to be cleaned so that it is optimally brought to the magnetic core. The magnetic core is easily accessible through the door for cleaning and control.

Rotobox RX

Rotobox Rotary Magnetic Separator is mainly used to separate fine and finest ferromagnetic contaminants from bulk solids that are prone to bridging or caking. By repeated contact of the bulk material with the magnetic rods very good separation efficiency can be achieved. The rotating magnetic bar matrix prevents clogging of the separator. To facilitate cleaning, an EASY CLEAN version and a fully automatic cleaning variant (AUTO CLEAN) are available.

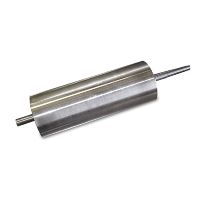

Roller Magnet WM

Roller magnets are used to separate ferromagnetic impurities from bulk solids on conveyor belts. They replace the discharging roller at the conveyor end. The magnetic roller is particularly suitable for medium and coarse contaminants. Even higher metal contaminants are effectively separated.

Magnetic Drum TM

Drum magnets are usually used at the discharge of a conveyor belt or after feeding with a vibrating conveyor trough for the separation of medium and fine metal impurities. The magnetic field extends over 180 °. The rotating stainless steel jacket conveys the magnetic impurities out of the working field of the magnet, where they then fall due to gravity. Through continuous cleaning drum magnets can be used even at higher levels of contamination.

Housed Magnetic Drum TMG

The housed drum magnet is a fully enclosed version of the drum magnet, including an electric motor, which can be easily integrated into existing systems. Guiding plates in the interior of the housing ensure that the bulk material is presented optimally within the effective range of the magnetic field. A large inspection opening facilitates maintenance and cleaning.

Cross Belt Magnet

Overband magnets are usually used to separate coarse ferromagnetic bulk materials over a conveyor belt. They can be used both in the transverse and in the longitudinal discharge. Even relatively heavy metal contaminants can be separated. Overband magnets are often used as machine protection for downstream shredding units.

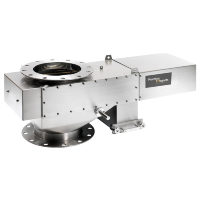

Rotobox AUTO CLEAN RXA

The rotary magnet system Rotobox AUTO CLEAN is mainly used to separate fine and finest ferromagnetic contaminants fully automatically from bulk solids, which tend to form bridges or to cake. By repeated contact of the bulk material with the magnetic rods very good separation efficiency can be achieved. The rotating magnetic bar matrix prevents clogging of the magnet system.

Magbox AUTO CLEAN MXA

The magnetic grid system Magbox AUTO CLEAN is used in production lines for the fully automated separation of fine and finest ferromagnetic particles. The cleaning is done sequentially, i. the production flow need not be interrupted during cleaning. Sensors constantly monitor the position of the magnets.

Liquimag AUTO CLEAN LMA

The fully automatic Liquimag AUTO CLEAN magnet system is used to separate even weakly magnetized iron particles in liquids and pumpable products. The cleaning takes place automatically by flushing out the separated impurities after the adjustable cleaning interval time has expired.